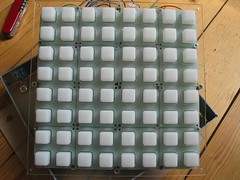

All done! xndr brought by a thicker faceplate earlier today. This means that the buttons dont stick up so far as they did before, and have a clearer, less wobbly action now.

The sticking buttons are fixed too (I think); through a combination of snipping away some excess parts of silicone to stop it bunching up around the screw holes, loosening the nuts that fasten the buttons to the inner faceplate, and careful positioning of the outer faceplate to maximise the gap round each button. If you look at the large version of the following photo, you can see where the silicone has been snipped away:

You can find some more photos of the box in different states at my

flickr photostream.

There are a few things I wish I'd known about earlier, here are a couple of the things I can remember:

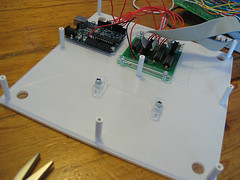

1. Solid core wire is good for breadboarding, but multicore wire would have been better for the 'real thing', since it's more flexible (easier to squash down, and out of the way) and less liable to snap. Wires snapped at solder points about ten times over the course of building this box, I came to dread opening it in case another one would break.

2. If you're thinking of using a Machinecollective enclosure, try to get hold of one before you start soldering, that way you'll be able to cut the wire to appropriate lengths for easier assembly.

3. The project will potentially take many hours to complete. I didn't keep a log of how long i spent on this, but its certainly much longer than I expected.

A huge thanks to Monome, for enabling people to create this kind of clone, and to everyone who's contributed their time and expertise to the Arduinome project.

Next: I'm busy building a mlr-inspired application in SuperCollider, to use with the Arduinome. I'll post a demo, and code samples here when there's something interesting to see.