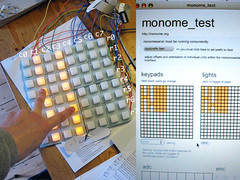

Xndr from Machine Collective is supplying a very nice enclosure for the project. (80 EUR). This projects also acts as a kind of beta test for his sparkfun monome enclosure parts.

An ingenious, almost seamless aluminium side panel with nicely rounded corners.

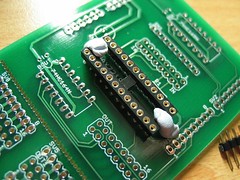

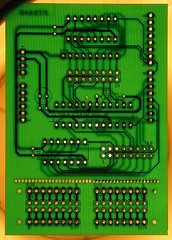

Here's the inner base panel. Notice that the shield does not sit on the arduino anymore (to keep the height of the unit to a minimum). Instead the two are connected with wires soldered to header pins. The shield is clamped in place by a few cleverly cut pieces of plastic tightened down with screws.

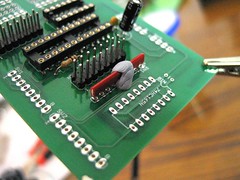

Also, It turns out that I needn't have removed the 'break off' part of the shield. Now I have the problem of how to secure this loose piece to the base of the enclosure.